SFB 1394 "Structural and chemical atomic complexity - from defect phase diagrams to material properties"

In January 2020, we started work in the new SFB 1394 together with our project partners at the RWTH, the Max Planck Institute für Eisenforschung in Düsseldorf (MPIE) and the FAU Erlangen-Nürnberg, with funding from the German Research Foundation (DFG). At IMM a whole team will be working within SFB1394 in the subprojects A01 (with MPIE), A02 (with FAU), A05, C01 (with MPIE), C02 and of course in the administration of the Z-project.

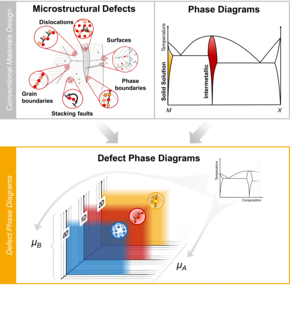

The motivation and the goal for the SFB can be summarised in this way (if you are more curious, you can find more details about the SFB and all subprojects on the SFB homepage www.sfb1394.rwth-aachen.de).

Precisely tailored material strength, formability and corrosion resistance are among the key properties of successful materials. By using sustainably available alloys, they make it possible to develop increasingly safe lightweight constructions for the mobility sector, build more efficient power plants and conserve valuable resources.

The properties of a material are determined by imperfections (defects) at the atomic level. These crystal defects can now be investigated down to the atomic scale with the help of new experimental and computer-based methods. The main objective is to use the knowledge of the atomic structure and chemistry of a material to describe and predict the stability of certain defects and to link these to material properties. In this way, a tool for material design is to be developed which will bring about a paradigm shift in the description of metallic materials.

In the SFB, all projects will work on a single material system: Mg-Al-Ca, its solid solutions, intermetallic phases and the creep-resistant in-situ composites of both.